STANDARDS AND STANDARDS:

- Vietnamese standards: TCVN 3223: 2000,

- Vietnamese Standards: QCVN 21: 2010 / BGTVT, Part 6 - SW53

- International standard: NK

- Equivalent Standards: AWS A5.18 ER 70S-6, JIS YGW12

FEATURES AND APPLICATIONS:

Advantages of the GM-70S welding line is that the MIG / MAG welding method is 2.5 times more effective than electro-insulated arc welding, which is more versatile and flexible than automatic welding. class of welding space in the space, in the welding process produces less toxic gas.

- GM - 70S is a low - carbon welded wire, high content of manganese and silicon, sulfur impurities, extremely small Phosphorus, which produces high strength and toughness.

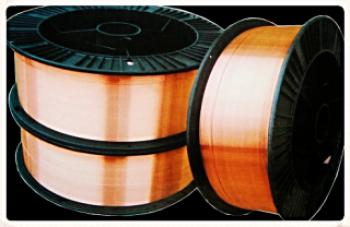

- GM-70S is manufactured with high precision, uniform wire direction, is coated with a high purity copper layer for preservation and welding process is stable.

Gemini GM - 70S Robots are mainly used in automotive, motorcycle, precision engineering manufacturing companies ... where robot welding is programmed.

PACKING:

Net Weight (Kg)

Net Weight for Soldering Robot (Kg)

15

125/250/350

WELFARE MECHANISM:

Gas mixture

Tensile

(N / mm2)

Flowability

(N / mm2)

Elongation

(%)

Crashed

- 29OC (J)

CO2

510 min

420 min

22 min

50 min

Ar + 18% CO2

510 min

420 min

24 min

60 min

CHEMICAL COMPONENTS OF WELDING (%):

C

Mn

Si

S

P

0.07 ~ 0.12

1.40 ~ 1.85

0.80 ~ 1.15

0.025 max

0.025 max.

DIMENSIONAL WELDING, ELECTRICITY AND WEIGHT LOSS:

Diameter (mm)

Ø 0.8

Ø 0.9

Ø 1.0

Ø 1.2

Ø 1.6

Welding current (A)

80 ~ 120

90 ~ 130

100 ~ 140

110 ~ 200

180 ~ 320

Welding voltage (V)

20 ~ 21

20 ~ 22

22 ~ 24

23 ~ 25

25 ~ 28

Liter of gas per minute

8 - 9

9 - 10

10 - 11

12 - 13

16 - 18

MANUAL INSTRUCTION:

- Prepare all labor safety factors before welding. Welding power is stable

- Remove dirt such as oil, rust on the surface of the weld. Weld edge forming a full gap, conduct the welding steps in accordance with norms.

- Cleaning welded wire, wire rope, adjusting the appropriate wire guiding mechanism for welding wire is steady conduction. Do not let the welded wire tangle, folded deformation.

- When welded wire is moist, or dusty, welding is smoke, firing and unstable, welded holes. Store welded wire in dry place, wrap it tightly, avoid dust, wet, avoid contact with welding wire surface.

- Select the welding current and always maintain the amount of air protection guided, shielding the maximum wind to be able to get deep welding, no defects, high work ability.